sCML has a state-of-the-art Quality Insurance System in place to ensure that all of our products are consistent and dependable.

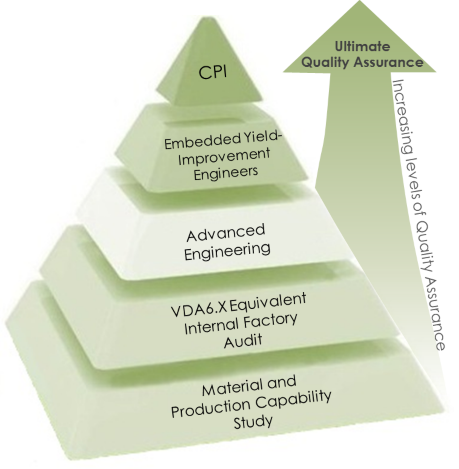

The quality assurance system can best be explained by the Quality Pyramid, which consists of 6 levels that progressively increase by sophistication. The first step of the system is the most fundamental. In order to proceed to a further-refining higher level, the preceding levels need to be completed. All six levels must be fully engaged to provide the utmost security and reassurance.

-

1. Material and Production Capability Study

The first step of our quality system is to ensure that our partner factories’ materials are up to standard and have sufficient production capacities to handle new orders effectively. In order for us to do this, we have developed physical labs in our partners’ factories in China and Germany which include the following test chambers:

• Thermo-shock Chamber KINETIC-B2

• Constant humidity / heat Chamber BE-TH-105L8

-

2. VDA6.X Equivalent Internal Factory Audit

We perform Internal Factory Audits on our suppliers three times a year. Driven by the high requirements from certain industries, we evaluate our suppliers with a stringent high-quality bar before qualifying in order to ensure product reliability and to maximize customer satisfaction.

-

3. Advanced Engineering

Our engineering team screens all projects before order data is transferred to factories in order to avoid production hiccups and increase efficiency and quality standards right from the get-go. Utilizing our expertise and experience, we streamline the complex and time-consuming communication processes between our client and suppliers. This allows customer to focus their time and resources towards their core business competencies.

-

4. Embedded Yield-Improvement Engineers

sCML positions embedded onsite QA and QC teams within partner factories. These teams understand the production process inside-out and back-to-front. They have the technical expertise to provide rapid decentralized and close-to-the-action engineering support inside the factory. Here are some of the tools deployed: 55, PDCS, KPI.

-

5. Continuous Process Improvement (CPI)

Continuous Process Improvement is another important aspect of our quality philosophy. We strive to continuously drive improvements into our factory partners. At the same time, we constantly find state-of-the-art equipment and technologies to make PCB production as efficient and sophisticated as possible. This is how sCML succeeds in high customer satisfaction.

© 2013 - Supplier CML Management Ltd. All Rights Reserved.